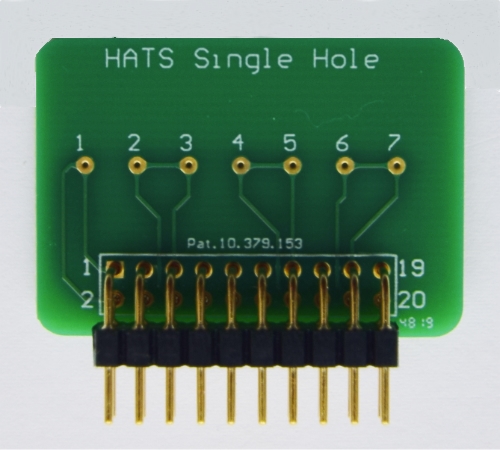

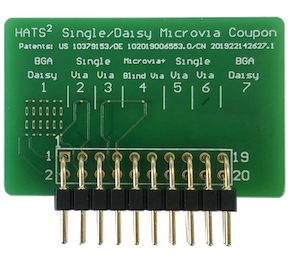

The HATS²™ Single Via Coupons*

Move Slider to See Front / Back

Move Slider to See Front / Back

The HATS²™ Single Via Coupon* uses Patented Technology to allow accurate, high current, micro-ohm precision, 4-wire resistance measurement of 7 Single Via Structure or Daisy-chain test nets in a HATS²™ Tester. This allows accelerated Reliability, Robustness and Component Attachment Process Simulation testing to occur on low resistance test nets (<0.001 Ohm) in a HATS²™ Tester during temperature exposures between -65°C and 265°C. Click on the questions below to see answers to inquiries that we routinely receive regarding the HATS²™ Single Via Coupon*.

Whats the difference in Testing Daisy Chains vs. Single Via Structures?

Multiple via structures daisy-chained together have historically been tested to asses via reliability, robustness or component attachment process survivability in an attempt to obtain some sort of statistical significance in via sampling. One problem with a daisy-chain of via structures is that depending on design, 70-90+% of the measured resistance comes from the circuit traces connecting the via structures together and not from the actual via structures themselves.

A typical single plated via structure has a resistance less than 0.001 Ohms. In a 0.200 Ohm daisy-chain net, only 0.020 to 0.060 Ohms represents a plated via structure's resistance. A 10% crack/separation in ALL of the plated via structures at the same time, would only result in a 1 to 3% change in daisy-chain resistance and would not trigger a failure event. Even a 30% crack/separation in ALL the plated via structures in the daisy-chain at the same time would not exceed the typical 10% resistance change failure criteria for daisy-chain test nets. The assumption that all the plated via structures in a daisy-chain will fail at the same rate is highly unlikely and it would take a 95+% crack/separation of one or a few plated via structures to register a 10% failure change in the resistance of a typical daisy-chain of plated via structures. A 0.001 Ohm change in a 0.200 Ohm daisy-chain (representing an ~50+% crack/separation in 2-3 plated via structures), would read as a .5% change in daisy-chain resistance, a value that would be seen as electrical noise or slight shift in temperature of the test chamber and would not even be noted.

Each 1°C change in temperature within a test chamber results in ~0.393% change in the electrical resistance of copper. Typical Shock/Cycling Chambers are rated at +/- 1.5°C which equates to 1.18% in electrical resistance variation just due to acceptable temperature tolerance within the test chamber.

It is clear that daisy-chains of plated via structures are only electrically sensitive to the end of a via structure's failure and cannot readily determine when a plated via structure begins its failure process. Daisy-chains certainly have their place in via structure reliability & robustness testing as they can determine when a plated via experiences complete failure, but the testing of single via structures is the only way to observe cracks/separations in plated via structures from their initiation through to failure.

A typical single plated via structure has a resistance less than 0.001 Ohms. In a 0.200 Ohm daisy-chain net, only 0.020 to 0.060 Ohms represents a plated via structure's resistance. A 10% crack/separation in ALL of the plated via structures at the same time, would only result in a 1 to 3% change in daisy-chain resistance and would not trigger a failure event. Even a 30% crack/separation in ALL the plated via structures in the daisy-chain at the same time would not exceed the typical 10% resistance change failure criteria for daisy-chain test nets. The assumption that all the plated via structures in a daisy-chain will fail at the same rate is highly unlikely and it would take a 95+% crack/separation of one or a few plated via structures to register a 10% failure change in the resistance of a typical daisy-chain of plated via structures. A 0.001 Ohm change in a 0.200 Ohm daisy-chain (representing an ~50+% crack/separation in 2-3 plated via structures), would read as a .5% change in daisy-chain resistance, a value that would be seen as electrical noise or slight shift in temperature of the test chamber and would not even be noted.

Each 1°C change in temperature within a test chamber results in ~0.393% change in the electrical resistance of copper. Typical Shock/Cycling Chambers are rated at +/- 1.5°C which equates to 1.18% in electrical resistance variation just due to acceptable temperature tolerance within the test chamber.

It is clear that daisy-chains of plated via structures are only electrically sensitive to the end of a via structure's failure and cannot readily determine when a plated via structure begins its failure process. Daisy-chains certainly have their place in via structure reliability & robustness testing as they can determine when a plated via experiences complete failure, but the testing of single via structures is the only way to observe cracks/separations in plated via structures from their initiation through to failure.

Why Test Single Via Structures Now?

Understanding the mechanics of via structure failure is important to tracing the root cause of failure and implementing corrections to the manufacturing process. Knowing when your plated via structures start to fail is important to robustness & reliability assessment, material selection and process control. Being able to see the initiation point of via structure's failure with a Single-Via Structure rather then the end of the via structure's failure with a Daisy-chain can enable a better understanding of differences in the manufacturing process and makes failure analysis easier as you know the exact via structure where the failure occurred. As Via Structures become more complicated and combine multiple technologies to form increasingly complicated structures, having sensitivity to measure small resistance changes resulting from mechanical changes in the via structure is paramount to understanding the interaction and failure mechanisms between these connected structures.

Is Single Via Structure Testing New and Unproven?

In 2009, a committee from a German automotive manufacturers group (ZVEI) published a method for testing single via structures during dual chamber thermal shock/cycling and much of the automotive industry has since adopted this methodology a a tool for via structure reliability.

I have years of Daisy-chain data, How will I correlate to Single Via Structure Testing?

The Patented HATS²™ Single Via Coupon* is able to test 7 Via Structure Nets. Each of these Single Via Structure Nets can be replaced by a Daisy-chain net. This allows the HATS²™ unit to collect electrical resistance data from BOTH Single Via Structures and Daisy-chain test nets on a single test coupon. Designers can include 1 or 2 daisy-chain nets along with 5-6 single via structure nets on the same HATS²™ Single Via Coupon*. This should provide a bridge to historical data and create opportunity to see the difference between single via structure and daisy-chain net test results.

How can I use the patented HATS2™ Single Via Coupon*?

The HATS²™ Single Via Coupon* uses Patented Technology for Test Coupon designs. In order for a company to use this technology in their test coupon designs, they must sign a licensing agreement with the patent holder Reliability Assessment Solutions Inc.. Licensing terms and fees will be determined on a case by case basis, but will have reasonable and nondiscriminatory terms and conditions to applicants desiring to obtain such a license. To inquire about a license to use the Technology of the HATS²™ Single Via Coupon* please use the CONTACT form in the Navigation Bar.

How can I get statistical significance testing only 1 via structure?

Each Patented HATS²™ Single Via Coupon* contains 7 single via structure nets. Each of these 7 Single Via structure nets can be changed to a daisy-chain to allow a mix of single via structure and daisy-chain net data to be collected. Testing 36 of these coupons in one HATS™ Chamber load, you get a sampling of 252 nets of single via structures (or single via & daisy-chain) nets while being able to accurately track the initiation and progression of cracks/separation in each via and correlate to historical information with included daisy-chain nets.

The assumption that a Daisy-chain net has statistical significance to the PCB's they represent in is basically inaccurate. To obtain "significance" from a sampling of via structures in a daisy-chain, mathematical models can be used with assumptions made regarding the similarity and variability within the population of via structures on the PCB's that the daisy-chain represents. As an example, for drilled via structures, a "similarly manufactured" population might be made up of 1200 via structures drilled by a single drill bit. To obtain a result confidence of 95% with a margin of error of 5%, 125 via structures from this one 1200 via drill bit population would need to be in the daisy-chain. Most PCB panels have many more than 1200 via structures and so this 125 structure sampling would need to be repeated for each set of 1200 "similarly manufactured" via structures on the production panel. This would require an unreasonably large daisy chain coupon, manufactured in a way that represents the appropriate "significant" quantity of via structures from each population, which is not practical or feasible in most cases.

There are many issues with grouping "similarly manufactured" via structures to form a via population from which to calculate a statistically significant sampling size, but however you add it up, the numbers of via structures needed in a daisy-chain in order to get statistical significance is higher than what is being tested today.

Results from daisy-chains without many hundreds of via structures in them have little statistical significance to the production panels they represent and are a statistical "feel good" measures at best and at worst, could be hiding small increases in resistance indicating structural issues in the via. In order to test the high resistance associated with a large daisy chains, the current flow through the daisy-chain must be reduced significantly to prevent circuit heating that would change the daisy-chain's resistance. This also affects the accuracy and significant digits of resistance measurement. A 50% crack or separation in a single via structure would go un-noticed as it would only register a change of <0.0005 Ohms in a daisy chain resistance that might exceed 1 Ohm (.05% change). Even if we had several via structures with a 50% crack or separation, only noise would be seen in the measurements made.

Daisy-chains certainly have their place in via reliability & robustness testing to determine the end of via structure failure, but single via structure testing is the only way to monitor cracks/separations in via structures from their initiation through to failure.

The assumption that a Daisy-chain net has statistical significance to the PCB's they represent in is basically inaccurate. To obtain "significance" from a sampling of via structures in a daisy-chain, mathematical models can be used with assumptions made regarding the similarity and variability within the population of via structures on the PCB's that the daisy-chain represents. As an example, for drilled via structures, a "similarly manufactured" population might be made up of 1200 via structures drilled by a single drill bit. To obtain a result confidence of 95% with a margin of error of 5%, 125 via structures from this one 1200 via drill bit population would need to be in the daisy-chain. Most PCB panels have many more than 1200 via structures and so this 125 structure sampling would need to be repeated for each set of 1200 "similarly manufactured" via structures on the production panel. This would require an unreasonably large daisy chain coupon, manufactured in a way that represents the appropriate "significant" quantity of via structures from each population, which is not practical or feasible in most cases.

There are many issues with grouping "similarly manufactured" via structures to form a via population from which to calculate a statistically significant sampling size, but however you add it up, the numbers of via structures needed in a daisy-chain in order to get statistical significance is higher than what is being tested today.

Results from daisy-chains without many hundreds of via structures in them have little statistical significance to the production panels they represent and are a statistical "feel good" measures at best and at worst, could be hiding small increases in resistance indicating structural issues in the via. In order to test the high resistance associated with a large daisy chains, the current flow through the daisy-chain must be reduced significantly to prevent circuit heating that would change the daisy-chain's resistance. This also affects the accuracy and significant digits of resistance measurement. A 50% crack or separation in a single via structure would go un-noticed as it would only register a change of <0.0005 Ohms in a daisy chain resistance that might exceed 1 Ohm (.05% change). Even if we had several via structures with a 50% crack or separation, only noise would be seen in the measurements made.

Daisy-chains certainly have their place in via reliability & robustness testing to determine the end of via structure failure, but single via structure testing is the only way to monitor cracks/separations in via structures from their initiation through to failure.

Whats so special about the Patented HATS²™ Single Via Coupon*?

The Patented HATS²™ Single Via Coupon* contains 7 via structure nets. Each of these 7 via structure nets can be designed as either a single via structure or daisy-chain net to allow a mix of single via structure and daisy-chain data to be collected from each HATS²™ Single Via Coupon*. A single via structure net typically has a resistance less than 0.001 Ohms. Being able to measure percentage change at this very low resistance requires the ability to make accurate measurements below 0.0001 Ohms, a very challenging requirement which requires both adaptation of the test coupon and measurement system.

Resistance of a single via structure must be pulled out of the total resistance of the entire test circuit which contains Test Lead Resistance, Resistance due to variation in temperature of the sample, Drift (Meter, Wire, Chamber Temperature) and finally the via structure's actual resistance.

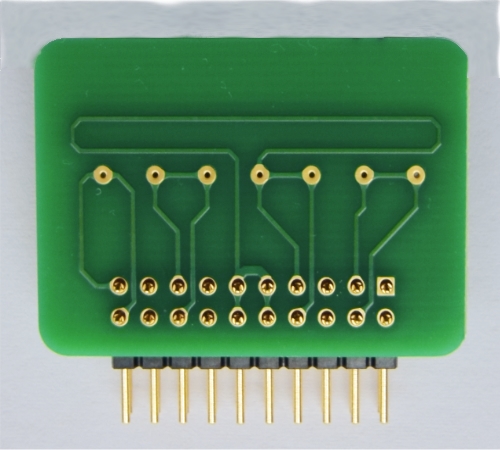

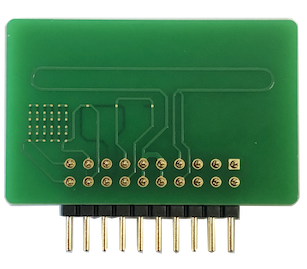

HATS²™ Technology addresses Test Lead Resistance by using 4-wire Kelvin Techniques which determine the resistance of the test leads in both directions, leading to a more accurate accounting of the resistance of the test leads.

HATS²™ Technology addresses Drift by using 2 specialized circuits built into the surface of the Patented HATS²™ Single Via Coupon*. Once of these circuits is >0.050 Ohms and one is <0.010 Ohms. By measuring these 2 circuits, a HATS²™ Tester can calculate Drift and remove it from measurements of Single Via Structure nets, giving a more accurate reporting of the net's value.

Resistance of a single via structure must be pulled out of the total resistance of the entire test circuit which contains Test Lead Resistance, Resistance due to variation in temperature of the sample, Drift (Meter, Wire, Chamber Temperature) and finally the via structure's actual resistance.

HATS²™ Technology addresses Test Lead Resistance by using 4-wire Kelvin Techniques which determine the resistance of the test leads in both directions, leading to a more accurate accounting of the resistance of the test leads.

HATS²™ Technology addresses Drift by using 2 specialized circuits built into the surface of the Patented HATS²™ Single Via Coupon*. Once of these circuits is >0.050 Ohms and one is <0.010 Ohms. By measuring these 2 circuits, a HATS²™ Tester can calculate Drift and remove it from measurements of Single Via Structure nets, giving a more accurate reporting of the net's value.

* U.S. Patent 10,379,153. German Patent 10 2019 006 553.0. Japanese Patent 7,291,045. Chinese Patent ZL 201922142627.1. Worldwide Patents Pending.

HATS² and the HATS² Logo are Internationally Registered Trademarks ® of Reliability Assessment Solutions Inc.

Copyright © 2016-2025 - Robert Neves - All Rights Reserved

Top